About us

We enable a rapid material

transformation — without

compromising performance

About Trifilon

Our vision

Grow your business by reducing carbon footprint

We develop climate-smart materials helping the world to switch from fossil-based plastic to climate smart materials. We do so by using a proven ingredient brand concept adopted by leading brands.

Our plug’n’play solution enables manufactures and brand owners to continue to offer consumers worldwide their high quality products – with a considerably lowered carbon footprint.

This way we enable a rapid material transformation for our partners and their consumers around the world, reducing CO2 emissions by at least 20%, often up to 90%.

We’re determined to make a change

Rooted in Sweden, we have a well-earned reputation for thinking long term.

We’re driven by curiosity and we’re determined to make a change. Our holistic perspective directs not only what materials we develop, but how we make them.

For us, sustainability isn’t just a policy, it’s in our DNA. And the

reason why we exist.

How we got here

Our growth has been organic and developed alongside our customers ever growing interest in high performance, sustainable plastics. We’ve learned by continually asking questions, making our fair share of mistakes and being naïve enough to believe that the status quo isn’t good enough. Our journey toward fully sustainable, circular plastics isn’t anywhere near over, but we’re happy to making steps every day in the right direction.

The Founders

Martin Lidstrand

Chief Technology Officer

Martin worked with the researchers at Linköping University who figured out a way to use hemp fibers to make a strong, lightweight material for vehicles. Martin recognized that hemp fibers solved a big problem – they made materials that were more environmentally friendly without sacrificing performance.

He bought the patents for the technology in 2012 and registered a company with partner Jeremiah Dutton. With a seed-financing round closed in 2017 and a second round in 2020, Martin developed from scratch an operational fiber-processing and specialized production line at Trifilon’s plant in Nyköping, Sweden. And he headed development of Trifilon’s business systems and delivery processes, helping the startup form into a dependable and innovative material supplier.

Jeremiah Dutton

Head of sales and marketing

Jeremiah had previously worked for Siemens Wind Power, first helping execute projects and later on the sales side. He met Martin in 2012 and helped develop Trifilon’s business idea by making industry and sales contacts in the Nordics and beyond.

By presenting Trifilon’s case for sustainability and winning difficult product trials, Jeremiah raised Trifilon’s visibility so that the company quickly raised investment capital for its plant. And he helped the company win its first major manufacturing partners, lifting the profile of the startup so that it has now won several awards and greater public interest.

Senior Staff

Jonas Ceder, CEO

Jonas was previously CEO of HLL Hyreslandslaget AB and before that he worked as an advisor and auditor for several owner-managed growth companies at a large auditing firm, Grant Thornton. Jonas has a master's degree in business administration from Stockholm University.

Martin Andersson, Finance, Purchasing & Logistics

Martin has previous experience as a business controller at both Mpya Finance and Unilabs. Martin has a master´s degree in business administration, economy from Örebro University.

Cecilia Renholm, Head of Administration, IR, HR & HSE

Cecilia has previous leadershipexperience from Systembolaget and hosting businesses. Cecilia has a master´s degree in business administration, leadership from University West, and an ongoing master´s degree in science, work environment and health from Mid Sweden University.

Teemu Timonen, CCO - Chief Commercial Officer

Teemu was previously working for UPM Biocomposites, where he hold roles related to sales, application and business development for biocomposite materials. He also have long backround from working with different kind of injection moulding and extrusion applications.

Thomas Kaldemark, Head of Production

Thomas has many years of previous experience from productionwork within ASP and Eberspächer Group.

Martin Lidstrand, CTO

Martin is one of the founders of Trifilon, and are today working as Chief Technology Officier.

Dimitrios Georgouvelas, Head of Materials

Dimitrios holds a PhD from Stockholm University on Materials Chemistry and a MSc in bio and nanomaterials from Uppsala University. He has experience as lab manager, as well as R&D and sales from BioFiber Tech AB. Dimitrios initially joined the sales team at Trifilon but soon switched to R&D.

Board of Directors

Per Allmér

Chairman of the Board

Member of the board since: 2023

Experience:

CEO PerMa-Way -present

President PPC, President EMEA, CCO & CIO - ABB/ADtranz/BT/Alstom

Ankie Bandstigen

Member of the Board

Member of the board since: 2021

Experience:

Faskunge Fastigheter - Founder and CEO

STIGA Sports - Chairman

Hanna Karlsson

Member of the Board

Member of the board since: 2023

Experience:

AMK Family Office - CEO

Mats Ekblad

Member of the Board

Member of the board since: 2023

Experience:

Inostra - Founder

Electrolux - Transformation Lead, Product Marketing Director, Director Adv. Development

Mats Karlsson

Member of the Board

Member of the board since: 2023

Experience:

Karlssons Fasadrenovering - CEO

Sven Mattsson

Member of the Board

Member of the board since: 2024

Experience:

Oriflame Cosmetics - Country mng, COO, CEO

Regovita AB - family office - 20 direct investments

Joe & Juice - boardmember

O’Learys - Chairman

Sushi Yama - Chairman

Master of Science, Stocholm School of Economics

AMP from Harvard Business School

What we offer

Today Trifilon manufacturers three material families, each with a unique performance and sustainability profile. We supply both standard stock grades and customized materials that are optimized to customer application needs.

Custom Materials

We believe in collaboration. And by working closely with customers, we’re able to act as a trusted materials development partner, fine-tuning our standard materials to better fit a specific application and its unique sustainability targets.

Material Families

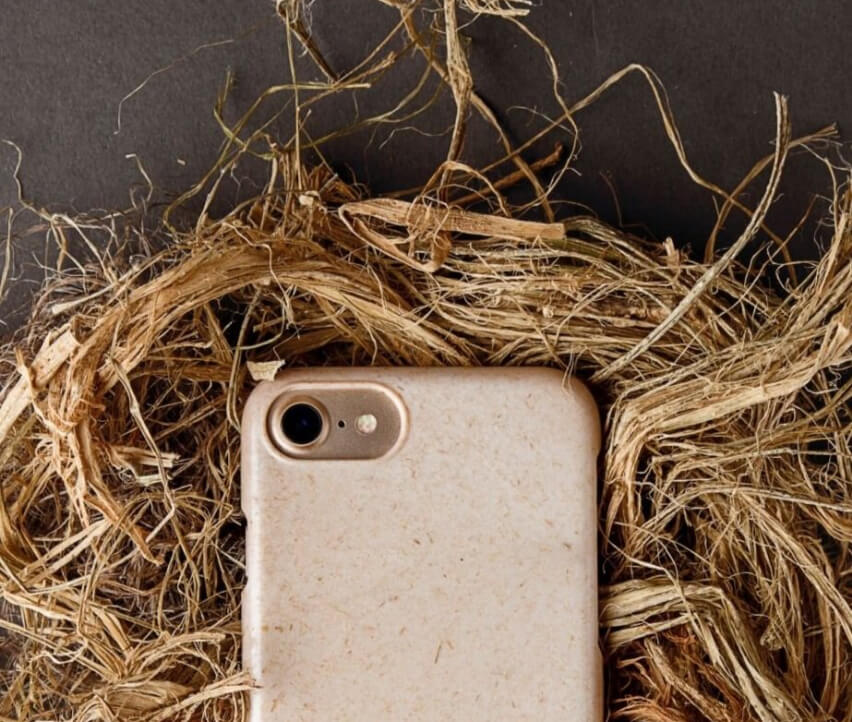

BioLite

Combines food and kid safe polymers with plant fibers to reduce weight, improve mechanical performance and lower CO2 footprint.

Switch

Our vegan offering. All main ingredients are plant based and all grades are industrial compostable.

Revo

Upcycling recycled plastic. Our lowest C02 footprint materials created with recycled plastic with plant fibers. Aiming for a CO2-neutral footprint.

FAQ

Generally biocomposite is the name for a composite, or a mix, of something biological with something artificial. For a few decades there have been technologies that mix plastics with plant-based material, which was frequently a waste stream. One example of an early technology simply mixed plastics with sawdust to make planks for decking. The sawdust was an inexpensive filler that provided acceptable mechanical properties for the application, being walked on.

Trifilon’s biocomposite technology represents a new generation of biocomposites. Trifilon’s 2nd generation of biocomposites use optimized plant fibers for their mechanical advantages, not simply as a filler. Trifilon’s plant fibers enhance the end material. In the case of BioLite, for example, you have a stiffer, reinforced plastic that has a vastly improved sustainability profile. Industrial hemp fibers provide that enhancement, and so Trifilon sources high-grade fibers from European farms.

Trifilon’s first material technologies exploited one of the plant-world’s strongest fibers, those that forms the stems of industrial hemp. Because that plant grows tall quickly it has evolved fibers with high tensile strength and light weight.

Making those plant fibers perform in a plastic composite was no easy task. Trifilon developed fiber refinement techniques to optimally marry the fibers to underlying plastic resins. Those techniques have been applied to other fibers successfully. Another strong fiber – those from the flax plant – have been used in some of our materials. And Trifilon recently added sustainable grown cellulose fibers from Scandinavian forests to its portfolio of fiber feedstocks. Ask if you’re interested!

Trifilon wants its partners to say exactly what they’re using. Our materials are biocomposites. They are plastics that include plant-based fibers.

Bio-based – All of our materials. This term can be misleading because it simply says that something in the material has a biological origin. So a batch of polypropylene with one leaf mixed into it is “bio-based.” Even more confusing, a drum of crude oil could be called “bio-based” because it has formed from carbon-based lifeforms millions of years ago!

Bio-plastic – Some of our materials. Again, this label can be used misleadingly to mean anything with a small plant-based component. But there is a better, more common usage that designates plastics mostly derived from plants. One of our product families, Switch, has its main ingredients from agricultural sources.

Biodegradable – No. This word refers to what happens to the plastic after it is used. A sloppy use of this word means the plastic magically disappears without toxic residue. That idea is nearly always misleading. A “biodegradable” plastic technology that rose to prominence in the 90s formed plastic bags that broke down into microscopic plastic pieces that toxify the ground or water. The technology is now banned in most countries.

The ideal afterlife of plastics would see their efficient reuse (recycling) and responsible disposal at the end of the material’s useful life. Trifilon Switch, for example, is industrially compostable. With applied heat and moisture it degrades to bio-compatible organic compounds. Other plastics are chemically recyclable. That means their chemical components can be separated for use in recreating new plastics, for example.

While our biocomposites can be melted down and re-granulated, the current sorting and recycling infrastructure does not accept Trifilon biocomposites or other sustainable, non-fossil based plastics. Improved sorting technologies and chemical recycling does offer a viable solution, but it is unclear if large-scale systems will be fully deployed in 3 years or 10 years.

Yes. Some of our bicomposites are approved for certain food-contact applications and for most child-contact applications. Ask for more details.

No. Trifilon delivers standard, uncolored granulates which can be colored using standard master batching. We do however have a number of sample plaques that show the aesthetic versatility of our materials. Evenly dispersed plant fibers are visible in the molded component, if desired. And while many other bio-based materials are dark or discolored, Trifilon biocomposites support much lighter colorations.

Trifilon delivers standard granulates, which are bagged, boxed, and shipped to the desired site – typically a manufacturing line.

Trifilon currently only delivers granulates and performs no molding itself.

Trifilon currently only delivers granulates and performs no molding itself.

Trifilon works with a number of stakeholders with different roles in companies including product developers, managers, owners, injection molders, designers, sustainability experts, and material engineers.

We encourage you to get in touch via email or telephone to discuss the needs of your product application and your sustainability goals. Or if you just want a sample and mechanical data, there is a form on our website.

Contact us

Looking for more sustainable plastics for your existing products or a brand new product? We’ll be happy to hear from you and tell you more about how you can add an extra USP to your products.