Revo

C02 Neutral

Plastic

Sounds ambitious? Absolutely! And that’s the long-term goal with Trifilon Revo®. Today, Trifilon Revo grades offers our lowest C02 footprint. Using consistent, high-grade recycled polymers mixed with plant fibers from non-food competing sources like hemp and wood cellulose, our aim is to achieve C02 neutrality without sacrificing performance.

Benefits with Trifilon Revo

- Up to 75% CO2 reduction compared to standard polyolefins

- Freedom to color — Not just grey or black

- Highly consistent mechanical and processing properties

- High recycled and bio content

- Matches important circularity narrative

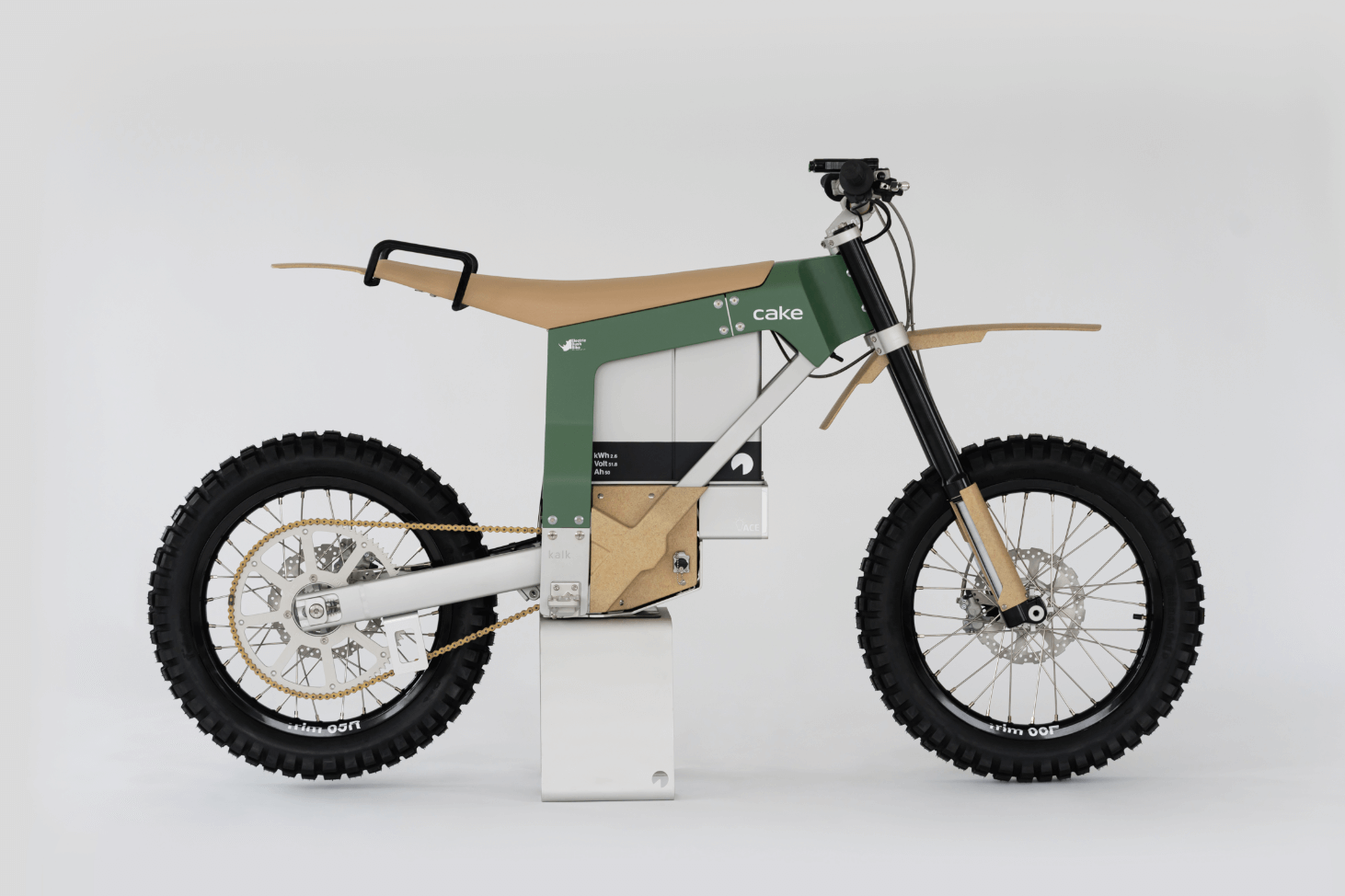

Cake

Kalk AP

Biocomposite:

Trifilon Revo

Sustainability Improvement:

92% C02 reduction

Key performance metrics:

- Extreme UV resistance

- High impact properties

- High fiber visibility

The Swedish company CAKE, which makes popular designer electric motorbikes, took on a project to equip field rangers in anti-poaching efforts in the African bush. They designed the high-performance Kalk AP to help rangers cover ground quietly – the electric motor emits little sound.

As the anti-poaching efforts have a spirit of conservation, CAKE designed its bike with sustainability in mind equipping it with solar panels for recharging on expeditions in wild terrain.

And the bike needed a lightweight, strong material for its plastic components. CAKE worked with Trifilon to develop a custom Revo grade that fills out the bike’s eco-profile.

Revo

in Depth

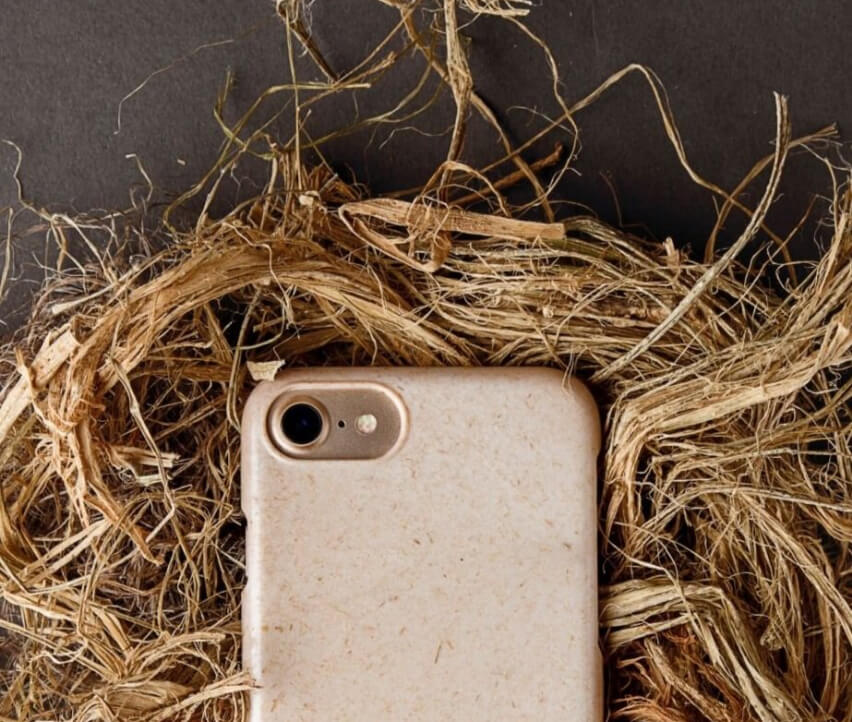

Upcycling Recycled Plastic

The ideal use of plastic in production would see its efficient reuse — old toys would be melted and reformed into new toys, for example. Trifilon Revo starts you down that path. It uses consistent sources of polymers from northern Europe that meet stringent EU regulatory requirements and reinforce it with plant fibers. And because both hemp and wood cellulose sequester carbon (takes carbon from the air to form its cells during growth), the total carbon calculations when using Trifilon Revo are even better than typical recycled plastic.

Circular narratives

When people think of solutions to our plastic problems they typically think along the lines of material feedstocks and disposal. But really the greatest good companies can do is finding ways to reuse old plastics. The ideal use of thermoplastics would see old products returned to their makers so the materials can be recycled, reinforced and made into new products once again.

What can be done now

In the best case, recycled plastics are sorted and reused in high performing applications. PET provides a good example, first forming bottles and then often being recycled into fibers for garments. But for other families of plastics often the best case is incineration for energy capture. Unfortunately, for many reasons, waste plastics often end up in landfills where it can sit for thousands of years or leak into streams, rivers and ultimately the ocean.

Trifilon Revo offers the reuse of a high-quality, existing plastic stream that can form high-quality and technically demanding products. Dramatically lower your products C02 footprint without sacrificing performance.

In depth info on our other materials

Custom

In need of an application specific material with unique properties – higher stiffness, specific UV or more impact?

BioLite

Combines food and kid safe polymers with plant fibers to reduce weight, improve mechanical performance and lower CO2 footprint.

Switch

Our vegan offering. All main ingredients are plant based and all grades are industrial compostable.