Recycling

The 260 million ton problem

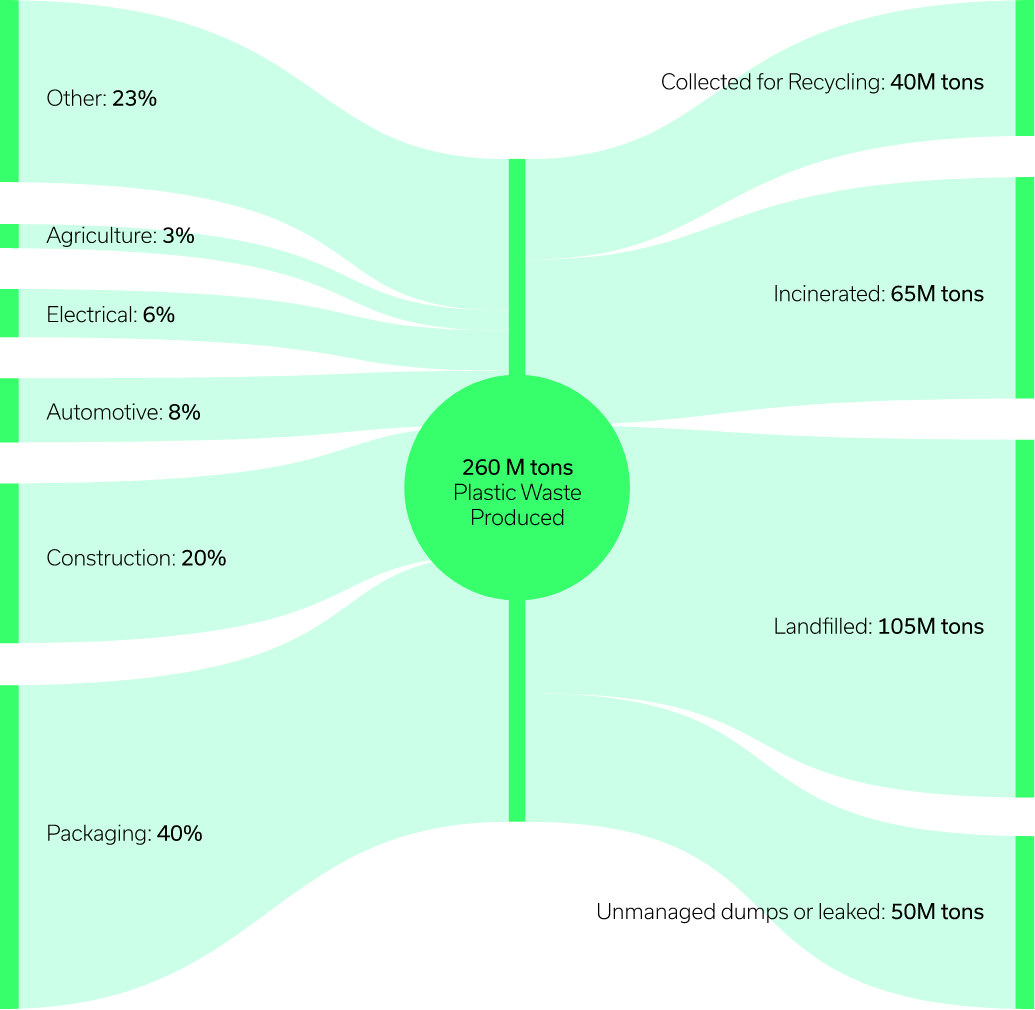

Did you know that every year people throw away more than half of their body weight in plastic? This tremendous amount of plastic waste totals more than 260 million tons every year and is projected to grow to more than 500 million tons by 2030.

In a perfect world, this plastic would be recycled into new products that live full, useful lives. Unfortunately, it is estimated that only 16% of this plastic waste is recycled. Why is this? The reasons are varied and very much localized. Some cities and countries lack collection systems, others don’t have plastic recyclers locally, meaning that there is no infrastructure to close the recycling loop. The biggest problem though is that new, fossil- based plastic is still very inexpensive. Going sustainable has a cost, but it’s something that more and more brands are choosing as consumer preferences shift and climate change awareness increases.

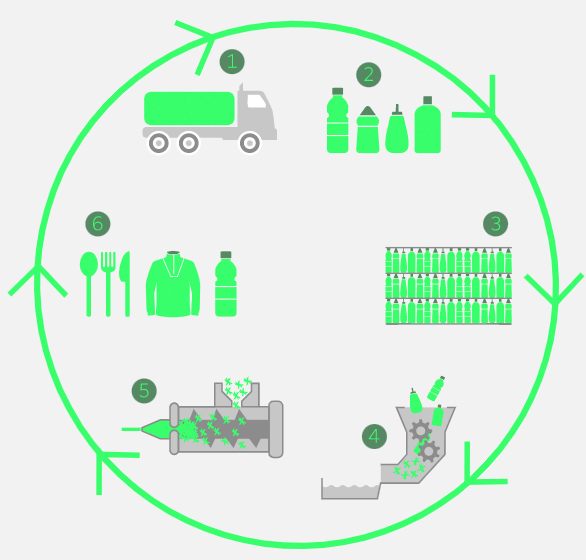

How Recycling Works

1. Collection

Plastics and other materials are collected in your community for recycling.

6. Reused again

The recycled plastic can be re-used again, but typically in less demanding applications than the original material.

5. Re-granulation

The shredded plastic flakes are melted down and re-granulated into pellets in an extruder.

2. Sorting

Using optical, mechanical and sometimes manual means to sort plastic waste into polymer type.

3. Baling

After being sorted, plastics are pressed into bales and sent to plastic recyclers for further processing.

4. Washing

Plastics are shredded, washed and checked for metals via strong magnets.

1. Collection

Plastics and other materials are collected in your community for recycling.

2. Sorting

Using optical, mechanical and sometimes manual means to sort plastic waste into polymer type.

3. Baling

After being sorted, plastics are pressed into bales and sent to plastic recyclers for further processing.

4. Washing

Plastics are shredded, washed and checked for metals via strong magnets.

5. Re-granulation

The shredded plastic flakes are melted down and re-granulated into pellets in an extruder.

6. Reused again

The recycled plastic can be re-used again, but typically in less demanding applications than the original material.

Current State of Plastic Recycling

Even in countries that have advanced recycling systems, a significant portion of plastics still go to incineration and energy recovery. And while this is typically a better alternative than landfilling plastics, more can be done.

Plastic Recycling Flows

Plastic Waste in Sweden

*Kartläggning av plastflöden i Sverige: Råvara, produkter, avfall och nedskräpning, SMED Rapport Nr 01 2019, Naturvårdsverket

Plastic Waste in Denmark

Plastic Waste Globally

Recycling FAQ's

While our biocomposites can be melted down and re-granulated, the current sorting and recycling infrastructure does not accept Trifilon biocomposites or other sustainable, non-fossil based plastics. Improved sorting technologies and chemical recycling does offer a viable solution, but it is unclear if large-scale systems will be fully deployed in 3 years or 10 years.

No. Recycling plastics downgrades its mechanical properties. Plastics are simply long chains of molecules arranged in repeating units. Most often, these chains are much longer and arranged in complex patterns that cannot be found in nature. And it’s this that makes plastic strong, light and flexible. Every time plastics are heated up though, as in a typical recycling process, these polymer chains shorten. It’s this shortening of the polymer chain that decreases a plastics’ quality and why it can only be recycled 2-3 times before it becomes no longer useful as a material.

The primary reason more plastics, including biocomposites, are not recycled is that virgin plastics are still too cheap. It is often still easier, cheaper and usually more profitable for brand owners to use new, virgin plastics when making products. Additionally, there are structural incentives to use plastics as an inexpensive energy source, especially in the Nordics where there is a significant capacity of waste-to-energy incineration plants. An under investment in recycling infrastructure and an over reliance on shipping plastic waste to China also meant that most countries were not prepared when China enacted its “National Sword” policy in January of 2018 and closed its borders to plastic waste imports.

This will depend on a number of factors including:

where is your product being sold? Is there a recycling collection system in the region? Do your customers understand that they can recycle your product?

how is your product designed? Is your product made from multiple materials; multiple types of plastics or plastics in conjunction with metal?

can your end-users disassemble your product if needed into its separate material parts?

Chemical recycling splits long polymer chains creating simpler chemical products such as monomers, crude oil or fuels. This splitting of the polymer chain requires a significant amount of energy and it is not clear currently if any C02 savings can be gained from this method of recycling. Depending on the energy source used to split these polymer chains, the C02 footprint for chemical recycling can even be worse than virgin fossil polymers. Mechanical recycling preserves the molecular structure of the polymer while shortening the overall polymer chain somewhat as it is remelted into granulate form. This form of recycling is less C02 intensive than chemical recycling, but leads to a degradation in the quality of the polymer.

Contact us

Looking for more sustainable plastics for your existing products or a brand new product? We’ll be happy to hear from you and tell you more about how you can add an extra USP to your products.