Biolite

Conventional plastics are made with byproducts from petroleum, natural gas, and coal. That means children’s toys have roots in offshore oil rigs, transport tankers, petroleum refineries, or hydraulic fracturing – industrial procedures that pose the risk of environmental catastrophe. Trifilon’s materials reduce reliance on fossil fuels – in some cases by up to 30%! BioLite® is a family of materials that blend non food competing plant fibers from hemp and Norwegian spruce with thermoplastics to form granulates for injection molding. Consumer products made with BioLite can trace ingredients to sustainable European farms and biodiverse Nordic forests.

Benefits with Trifilon BioLite

- Up to 60% CO2 reduction compared to standard polyolefins

- Aesthetics as you like - both visible and non-visible natural fibers available

- Improved haptics and mechanical properties

- Up to 30% less plastic in your parts

- Encourages sustainable farming and biodiverse silviculture

- Works with standard injection molding machines and tooling

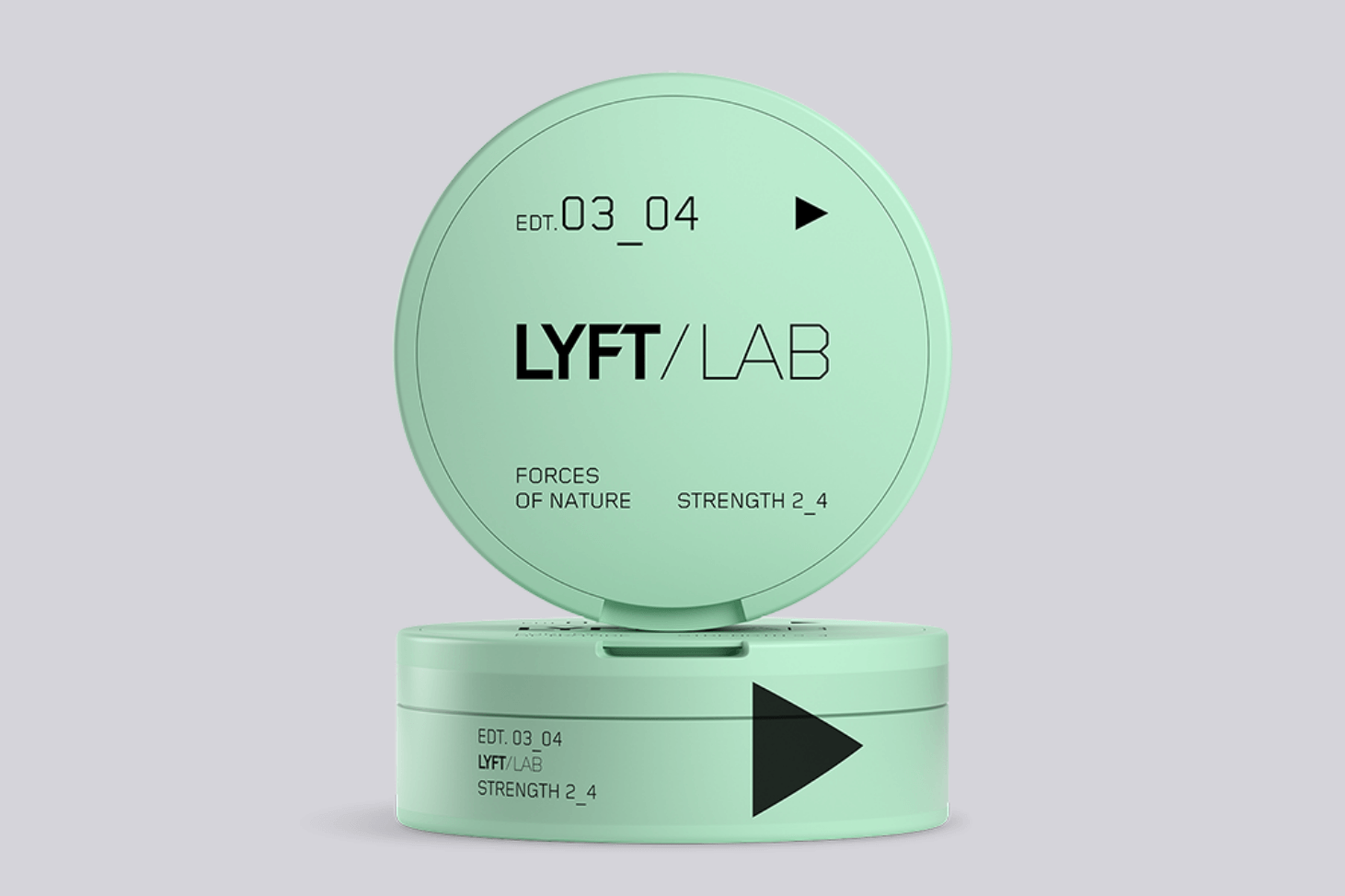

Lyft

Green Can

Biocomposite:

Trifilon BioLite

Sustainability Improvement:

33% less plastic

Key performance metrics:

- Optimized elongation

and flex - Migration safe according

to food contact compliance

Lyft, which produces a no-nicotine snuff or snus, wanted to begin working with sustainable packaging materials. Their highly-designed canister required a unique, high-performance biocomposite from Trifilon. That material forms the mechanically demanding product just as well as the original plastic recipe. But the new canisters, colored green, improve sustainability metrics, like the CO2 footprint, dramatically.

The plant fibers in the biocomposite even give the canisters a desirable haptic characteristic,

a warmer and more natural feeling.

And the canisters are still recyclable in regular plastic streams. Lyft sees this material as just the first step in a journey toward more sustainable packaging.

BioLite

in Depth

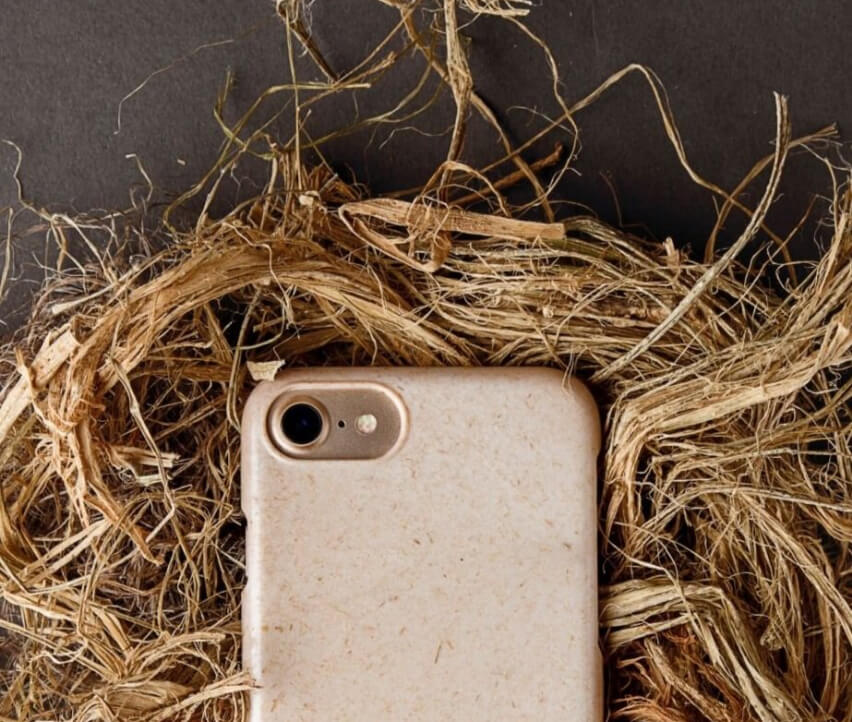

Looking sustainable

Products made with BioLite communicate a lot to your customer. It tells them you are committed to circular economies, near-to-home production, reducing fossil dependence, supporting biodiversity, and developing renewable feedstocks. Incorporating BioLite into your product also says you have upheld the high quality standards that customers have come to expect from your brand.

The optimized plant fibers make BioLite stronger than competing biocomposites. And due to their natural low density, they enable an easy light weighting option compared to conventional talc reinforced plastic materials. And when molded BioLite looks and feels more organic. Its matte finish can be speckled with plant fibers. More product designers are finding that an organic look quickly communicates that customers are making a sustainable choice.

The promise of natural fibers

The technology behind BioLite makes it the best, high-grade biocomposite. First, it’s easily processible. It does not present problems with special injection molding equipment or extremely narrow processing windows like other bio-based composites. BioLite can be processed at lower temperatures, often with improved cycle times, even in thin-walled packaging applications.

Secondly, the specially optimized fibers in BioLite means that it has mechanical advantages over biocomposites using other organic sources.

Third, the sorts of plant fibers used in BioLite are advantageous when it comes to sustainability and encouraging biodiversity. The hemp used in BioLite is grown as a rotational crop and doesn’t compete with food production, while the cellulose fibers come from PEFC certified Nordic forests. Both fibers are particularly good at sequestering carbon, a process researchers say is an important tool in hitting emissions targets.

We are your sustainable plastics supplier

Trifilon is ready to ship BioLite® granulates to your injection molding machines today. That means you can begin producing sustainable-choice molded components right away. Contact us to hear about our production capacities. Using our optimized plant fiber biocomposites in your products looks more organic and makes for stronger components.

In depth info on our other materials

Custom

In need of an application specific material with unique properties – higher stiffness, specific UV or more impact?

Switch

Our vegan offering. All main ingredients are plant based and all grades are industrial compostable.

Revo

Upcycling recycled plastic. Our lowest C02 footprint materials created with recycled plastic with plant fibers. Aiming for a CO2-neutral footprint.